Brochures | Project cases | Company info | YouTube & LinkedIn

Downloads – stay up to date!

The challenges of modern postpress

Projects have changed dramatically, especially in web printing and post press. Ten to fifteen years ago, the main focus was installing a press delivery system behind a new web press. Today, post-press projects are much more complex and demanding, including a variety of different requirements, such as:

- an overhaul & upgrade to improve productivity and to extend lifetime of the equipment

- the relocation of a system or even a whole operation

- the optimization of an existing line with new/refurbished equipment and/or additional automation

- the replacement of old equipment with new and/or refurbished equipment

- the merging of equipment from two lines, partially with equipment from different suppliers

Being a reliable solution provider is challenging. You need experience, market knowledge, technical know-how, the ability to translate very diverse requirements into efficient solutions, the strengths and creativity to support your customer base in an extremely difficult market.

IN-LOG | GAMMERLER and RIMA Atlanta form a strong team that meets these requirements in post-press, bindery, and packaging. We have a proven track record and a stable setup. Together with the MERTEN Group, we form a unique network of solutions, services, and possibilities from which our customers benefit.

Company Profile - who we are

YouTube & LinkedIn

IN-LOG | GÄMMERLER & the MERTEN Group

From 1922 to today – a long journey

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationTime to party – 100 years MERTEN Group

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe future – shaping solutions together

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationIN-LOG | GÄMMERLER on LinkedIn and YouTube

Product information and project cases

Product information post press for web presses

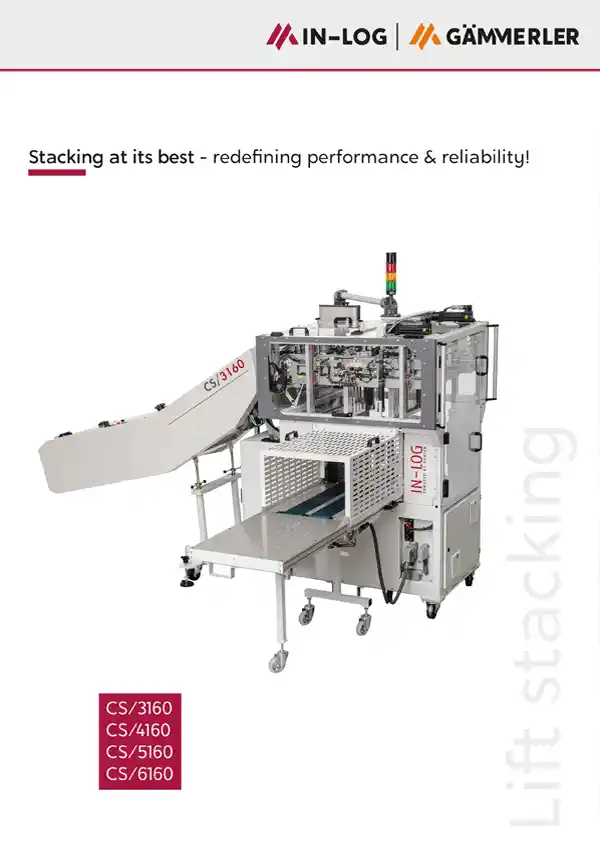

CS/3160 high-end compensating stacker

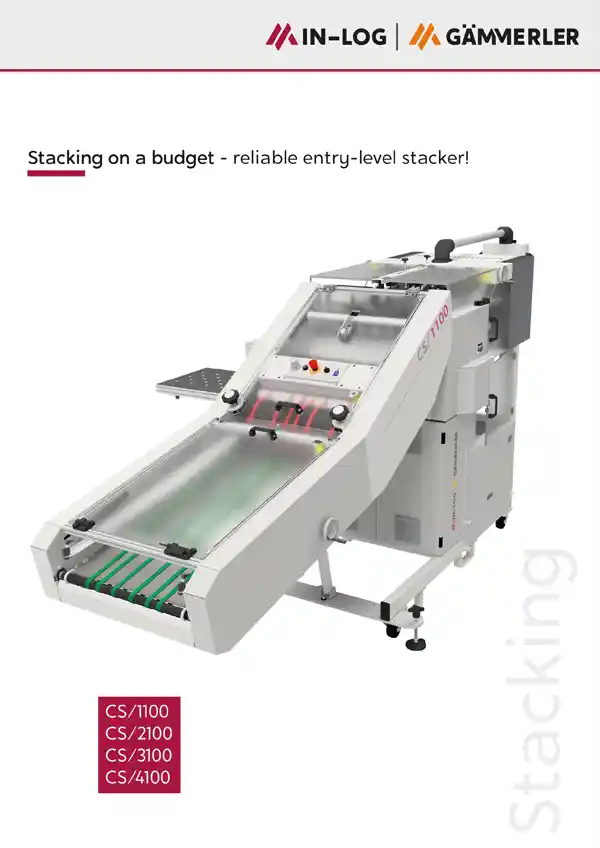

CS/1100 standard compensating stacker

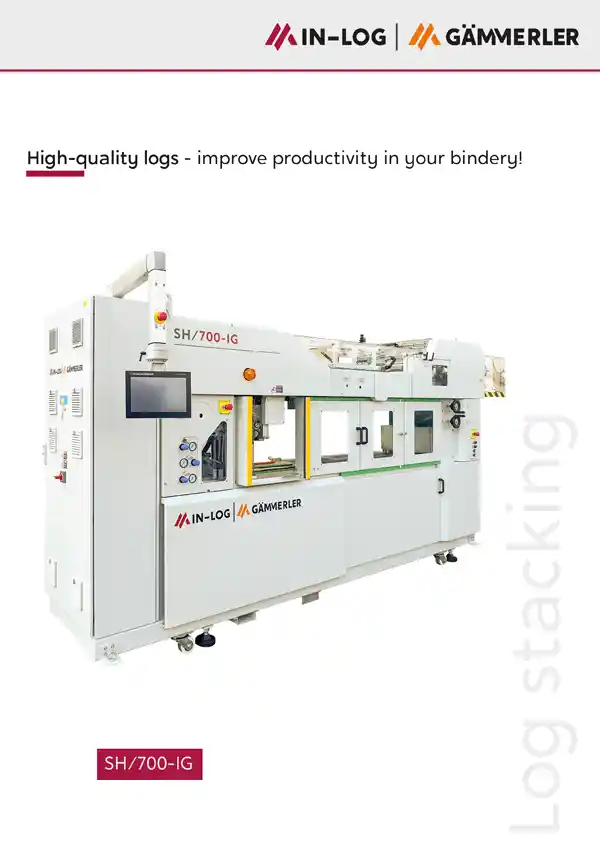

SH/700-IG log stacker

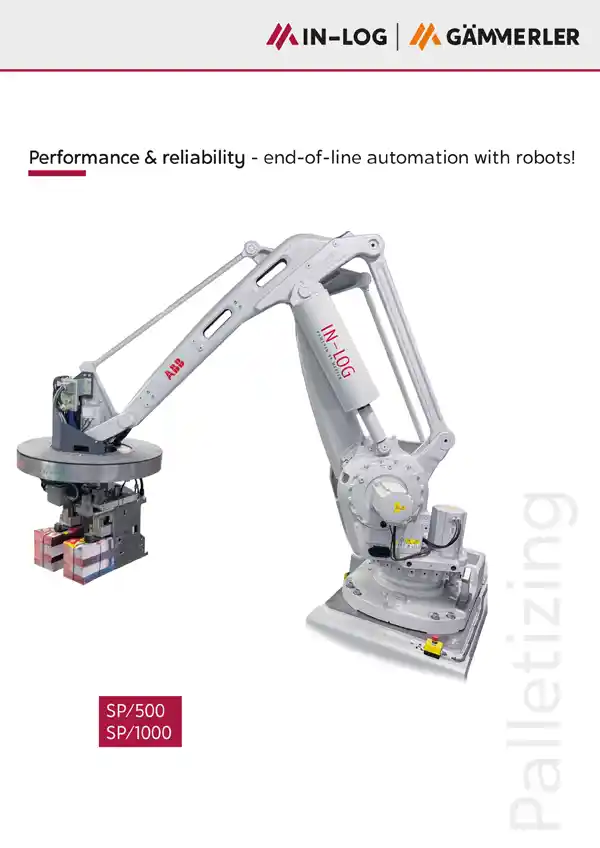

SP/500 and SP/1000 robots

ERIC high-performance mini-robot

VarioMailer IN-VM

Product information bindery and packaging

RS 11, RS 10/S, RS 33/S bindery stackers

The standard compensating stackers – from entry level to high-end – for saddle stitchers, perfect binders, gathering machines and digital lines – RS 11, RS 10/S, RS 33/S stacker.

RS 20/SW packaging stackers

RS 20/SW Packaging Stacker – Creates precise stacks of paper and cardboard products.

Project cases

Magazine & retail operation

- 16p press, heatset

- conveying, trimming, stacking

- magazine, digest & tabloid sizes

- 16 & 32p at up to 50.000 cph

High-volume retail

96p press with PCF & PFF folder, heatset

trimming, stacking, strapping, robot

mostly magazine size

24-48p at up to 100.000 cph

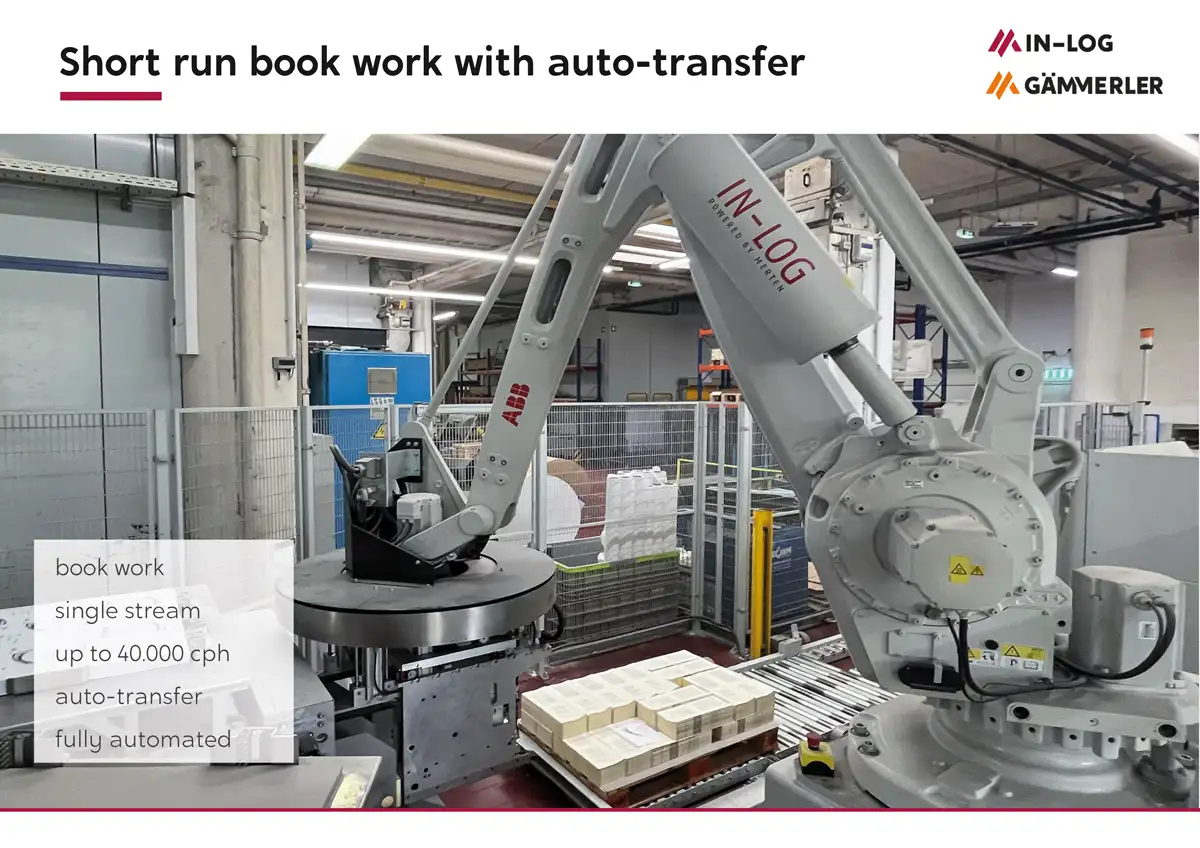

Ultra short run book operation

48p “ZMR” press, PCF folder, heatset

conveying, trimming, stacking, robot

mostly double-digest (DP) size

24-48p at up to 35.000 cph

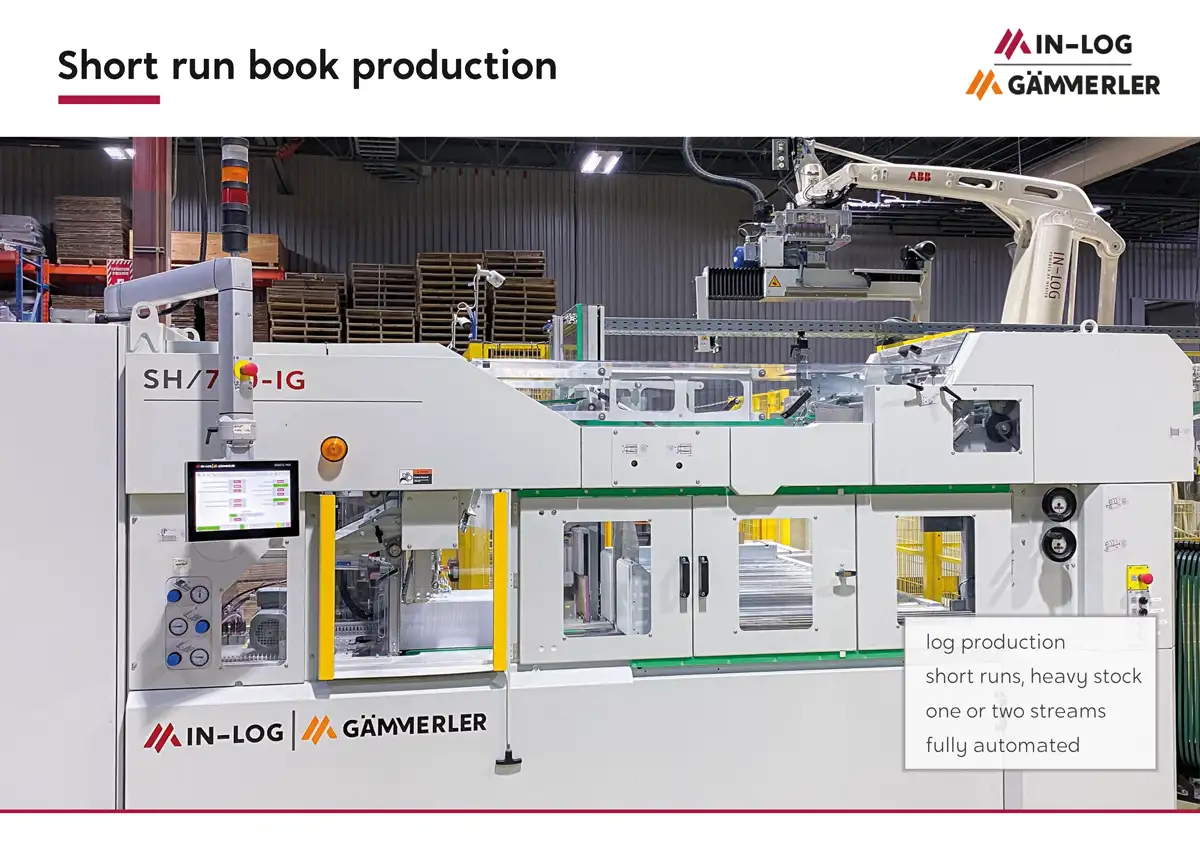

High-quality book operation

48p press, PCF folder, heatset

conveying, log stacking, robot

mostly magazine & tabloid size

24-48p at up to 40.000 cph

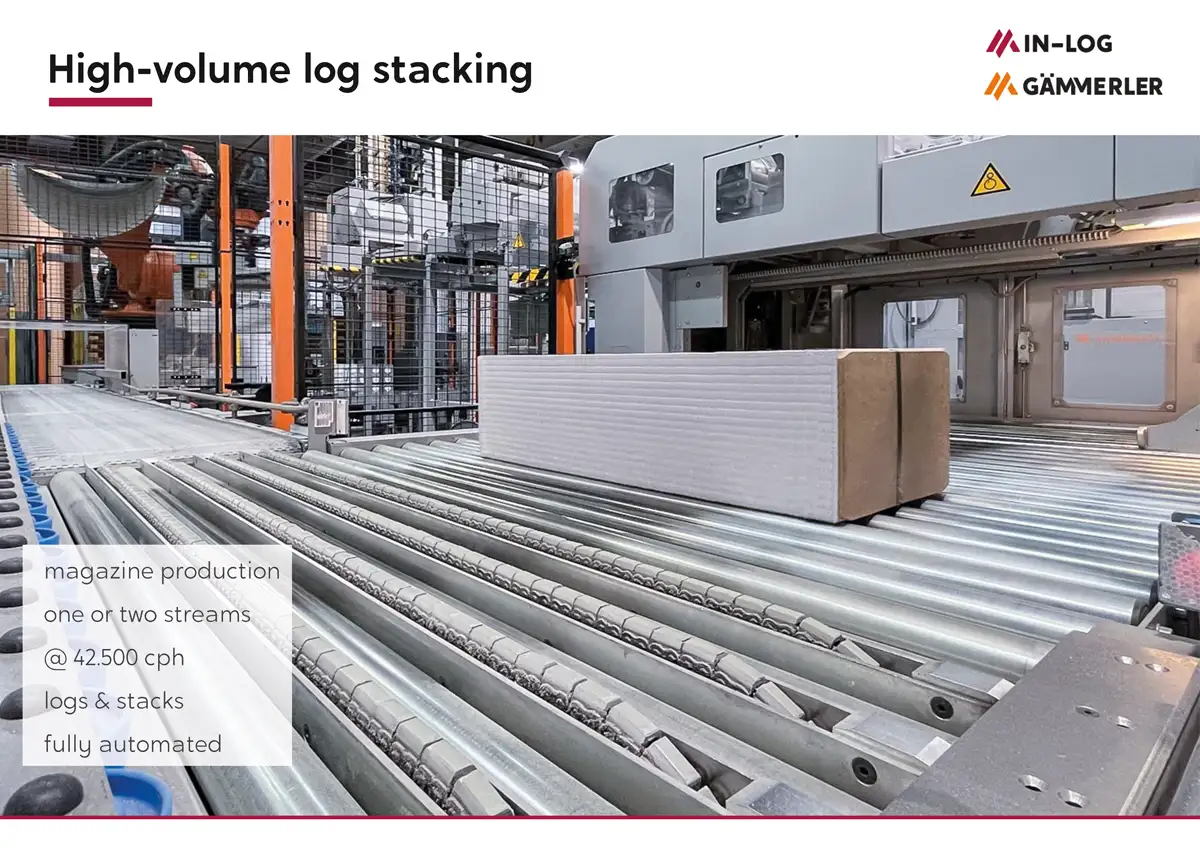

High-volume magazine operation

80p press, PCF folder, heatset

conveying, log stacking, robot

option: trimming, stacking

mostly magazine size

32-64p at up to 42.500 cph

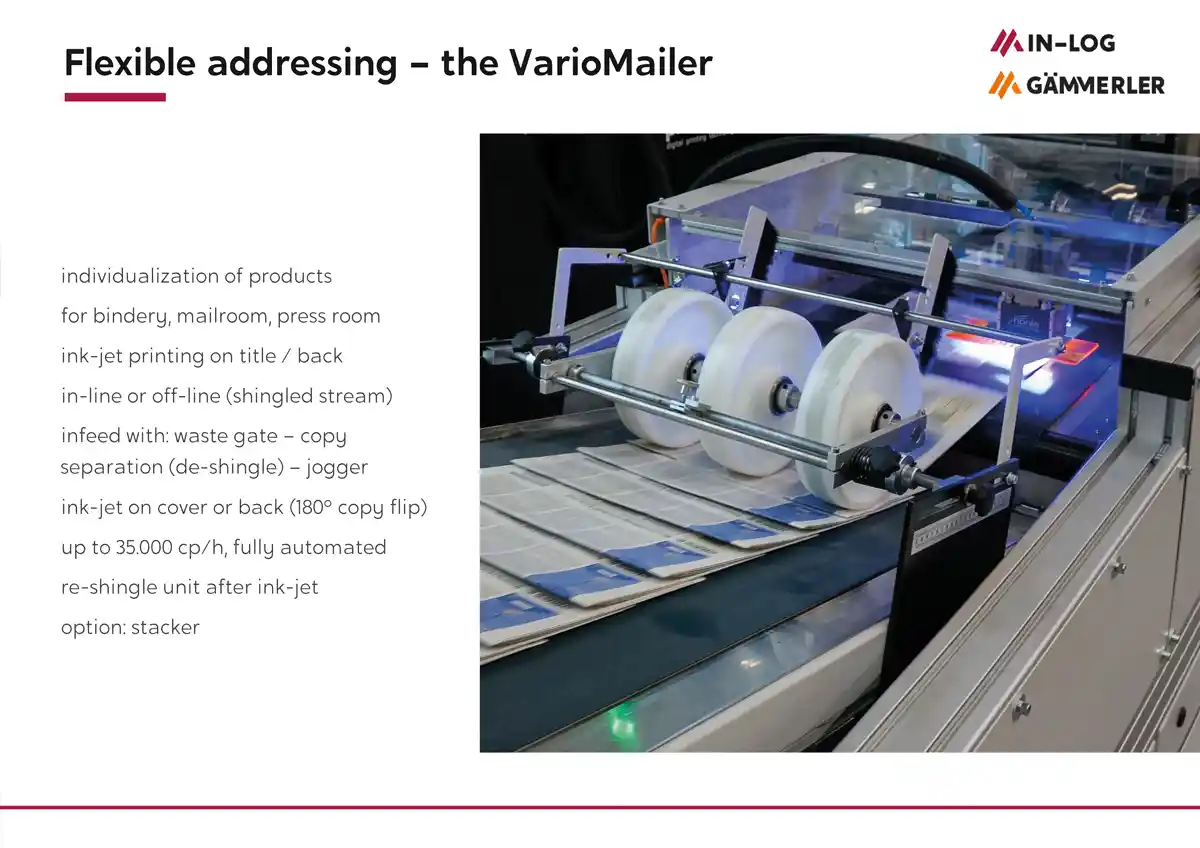

Single copy addressin

in the bindery and mailroom, in- or off-line

copy separation, addressing, stacking

optional product flip (180°)

8 to 128p @ up to 35.000 cph

High-volume retail printing

128p press, rotogravure

trimming &, stacking

magazine & tabloid sizes

24-80 p @ up to 120-000 cph

Special Solution - bindery automation

automatic log loading

from the pallets onto the stream feeders

for high-speed binders & stitchers (Ferag)

RS 20/SW packaging stacker – stacking of paper envelopes

automatic stacking of paper envelopes

shingled productstream at the infeed

up to 30.000 Ex/h

RS 20/SW packaging stacker – stacking of paper envelopes

automatic stacking of paper envelopes

shingled productstream at the infeed

up to 30.000 Ex/h

Terms and conditions

To avoid any surprises, here are our general terms and conditions.