You will be surprised how long Gämmerler machines will last. Our customized support packages will help you maintain performance and reliability for many years to come.

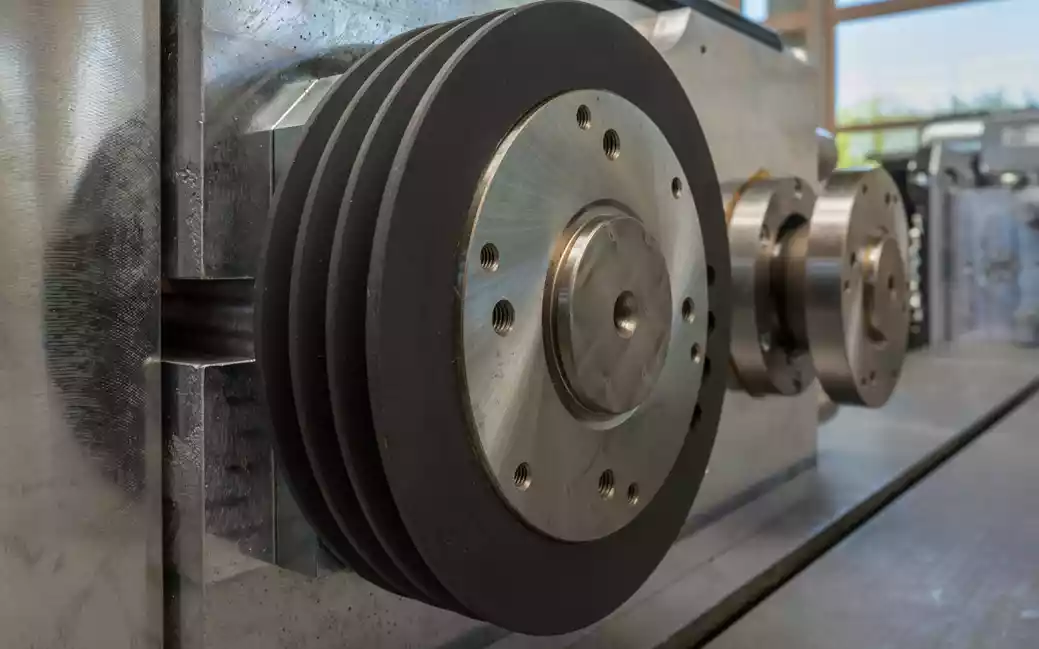

One of the pillars of our service is the provision of spare parts – today and in future. Our customer service team actively supports you in extending the service life of your Gämmerler machines - from simple trimmers or compensating stackers to complete systems. And should a part become obsolete, we provide technically equivalent replacements or develop machine-specific upgrade kits.

Downtime, maintenance costs, speed are suddenly becoming a problem and threatening productivity? A new machine would be the best solution, but it is not in the budget. Our factory rebuilt equipment with optional warranty bring 100% performance back to your plant at a manageable price. Talk to us, maybe you can even trade in your old machine.

The printing industry will continue to consolidate, merging sites and focusing on core production. This will lead to more press and equipment moves, often combined with overhauls and configuration upgrades to improve Postpress operations. Equipment relocations can be very complex and challenging projects, and choosing a professional partner is critical to the success of the project.

No productivity without trained personnel. We train you during commissioning and as a refresher during productive operation. Especially in times of high staff turnover, regular training can significantly increase Postpress productivity.

Depending on the project and objectives, it may make sense to consider a new machine or system. IN-LOG | GÄMMERLER can assist you in the design of a new solution, both with existing machines and with new machines or the combination of new and existing components. We carefully evaluate the technical and commercial advantages and disadvantages, discuss the best solution alternatives with our customers and realize the final version.

IN-LOG I GÄMMERLER is a leading Postpress solution provider and a brand of the Merten Group.